OVERVIEW

How to get a Five Rating from EHO

A brief guide on passing your next EHO inspection

In this article you’ll discover:

- A basic overview of how to achieve a five

- A detailed explanation of each point

- A brief explanation of how EHO calculate your rating

1. INTRODUCTION

Ensure you make a great first impression!

2. MUST HAVES

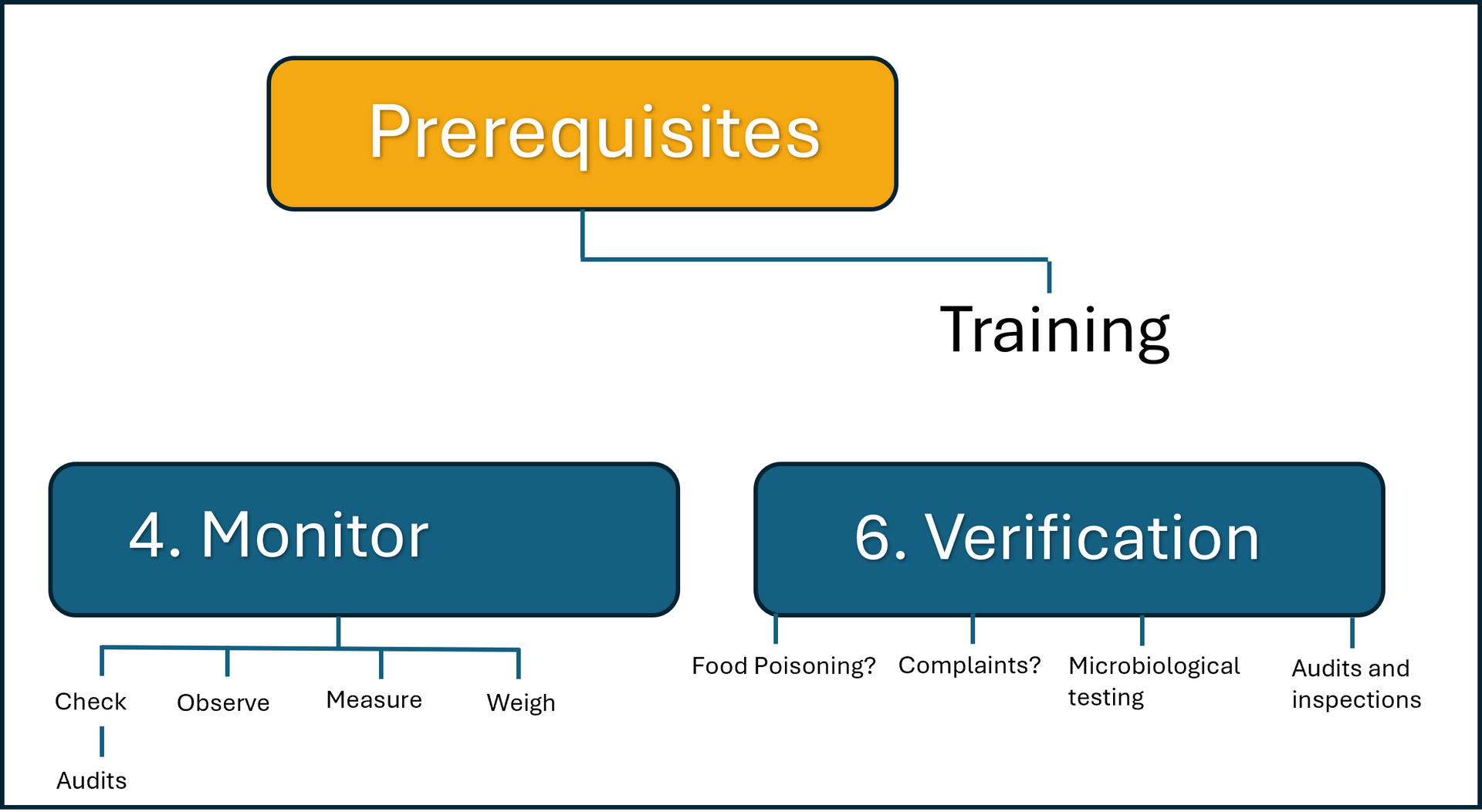

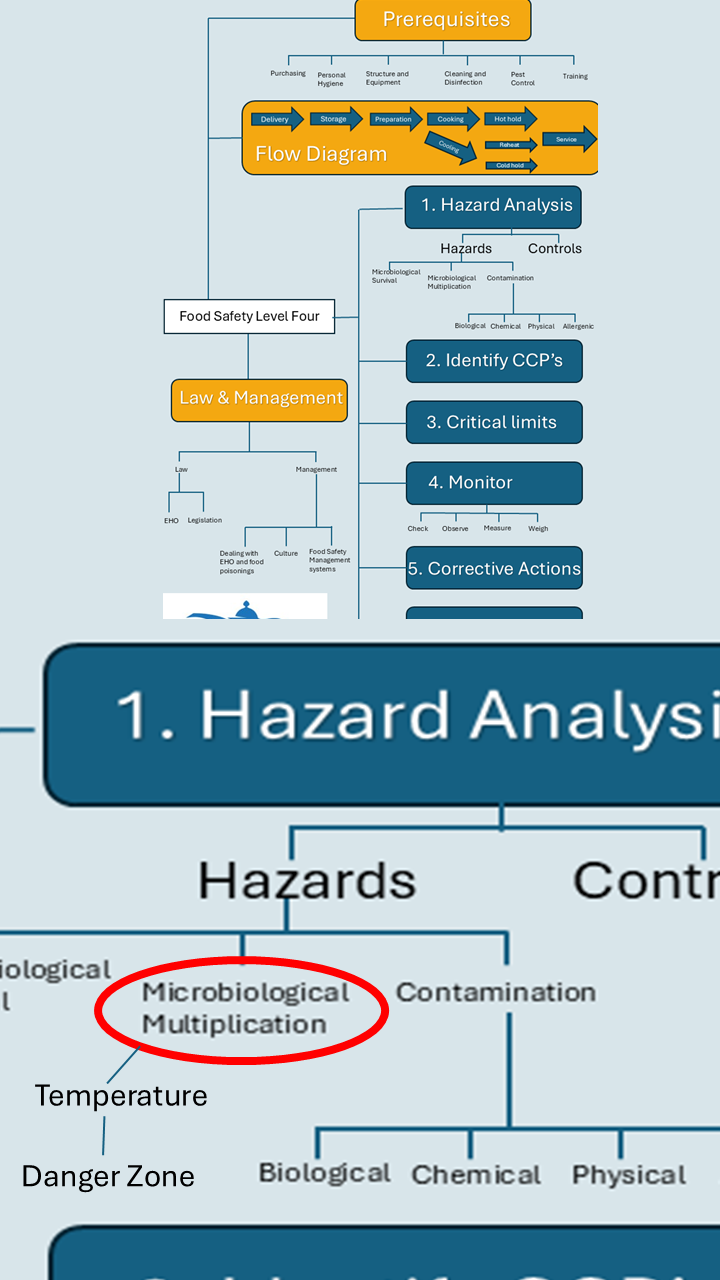

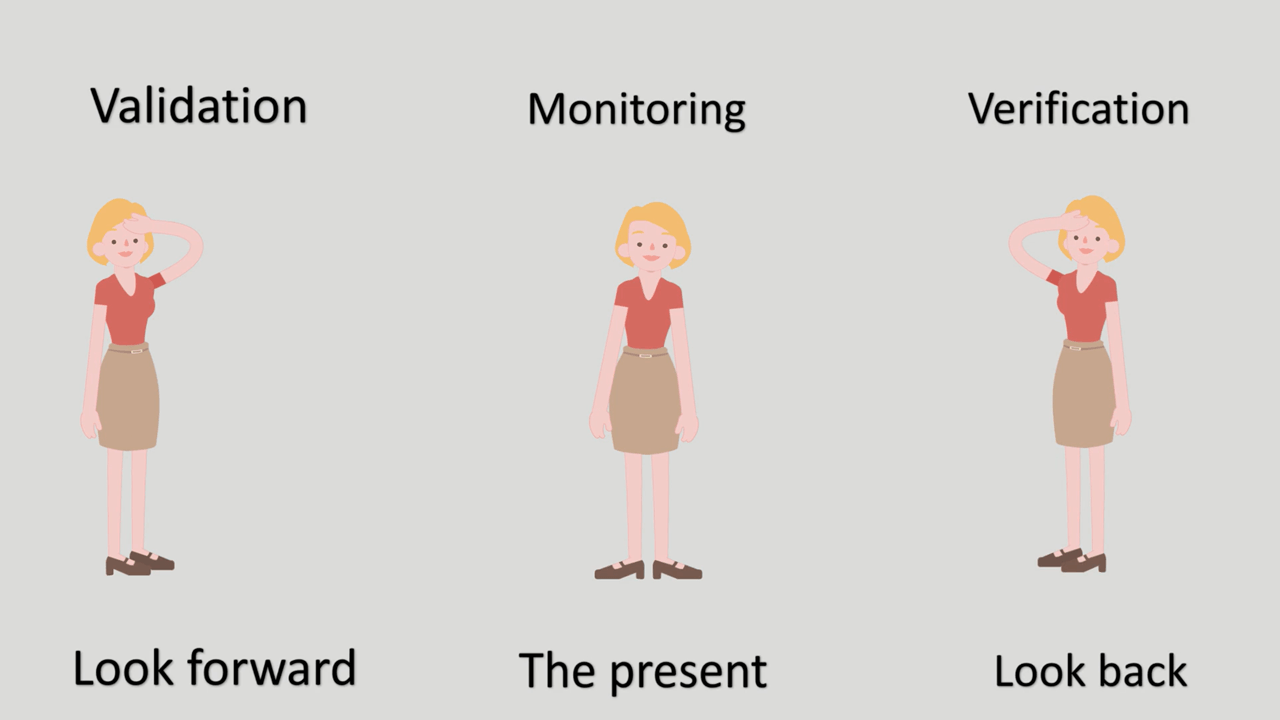

· A food safety management system based on HACCP principles

· Allergen information

· Training records

· Hot and cold running water

· Fully stocked wash hand basins

· The correct grade of sanitiser/disinfectant

3. FOOD PRODUCTION

· Separation of raw and cooked food

· Suitable cooling procedures (if applicable)

· Good personal hygiene

4. STRUCTURE, CLEANING, AND PESTS

· Smooth, cleanable surfaces, equipment in good condition

· High cleaning standards

· Pest free

5. STORAGE

· In date

· Correct temperature

· Correct storage practices

THE DETAIL

In this section you’ll gain a greater understanding of these basics. The advice is taken from thousands of hours auditing experience, and the creation of our online courses.

1. FIRST IMPRESSIONS

It’s also possible they are visiting following a complaint, or to investigate a food poisoning outbreak; it’s a good idea to find out the reason for their visit.

2. MUST HAVES

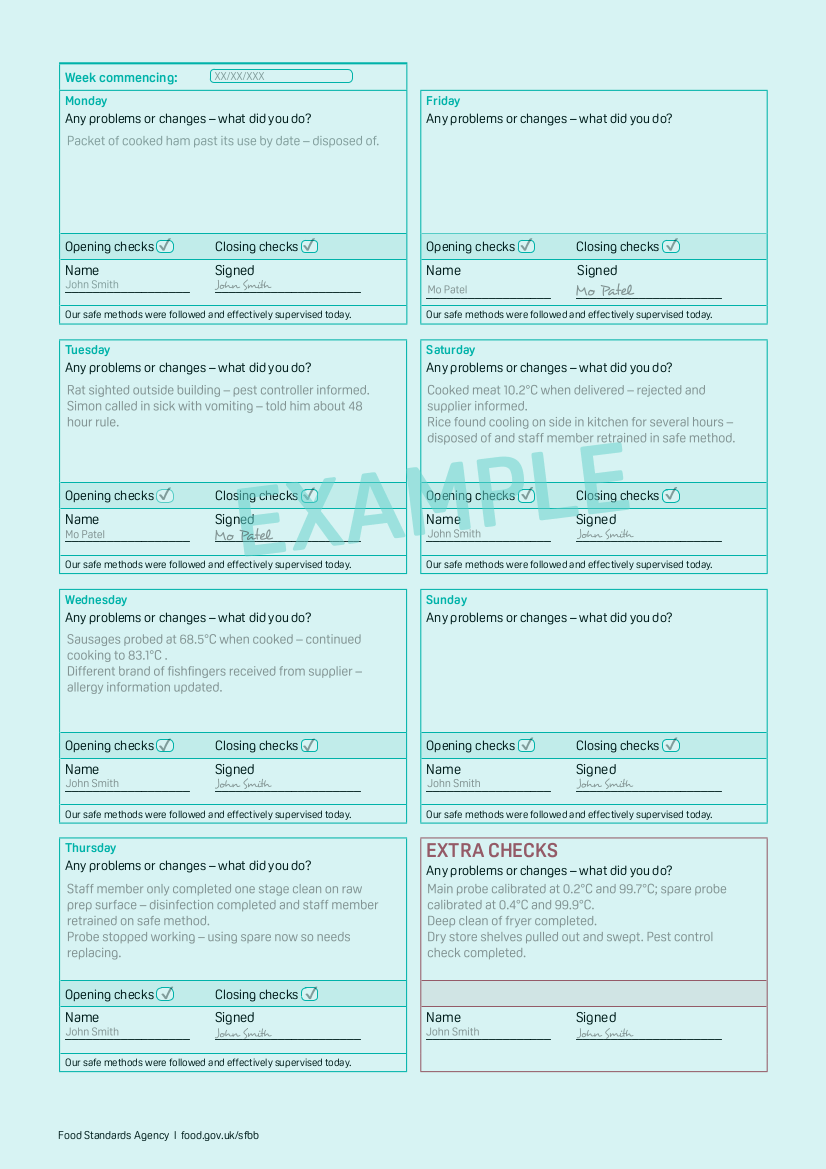

- Some EHO also expect you to record temperatures twice per day. It's not strictly a legal requirement to do this; but again, if you’re going above and beyond, it creates a great impression.

Safer Food, Better Business is not the only option available. You may be using a food safety management system developed by a consultant, or by an in-house team. Always make sure staff know where to find these documents.

ADDITIONAL RECORDS

Your EHO may request additional records including:

- Pest control records

- Training records

- Waste transfer notes.

We advise you to keep all these together in your “EHO” container to hand over as requested.

If it's not practical to keep all of these in a covered container; then provide a list so staff dealing with EHO know where to find them.

Remember, even if you’ve completed your Safer Food, Better Business pack, failure to produce on the day could result in a low score.

ALLERGENS

PROVIDING ALLERGEN INFORMATION TO CUSTOMERS.

You’ll need to ensure your allergy information is accurate AND available.

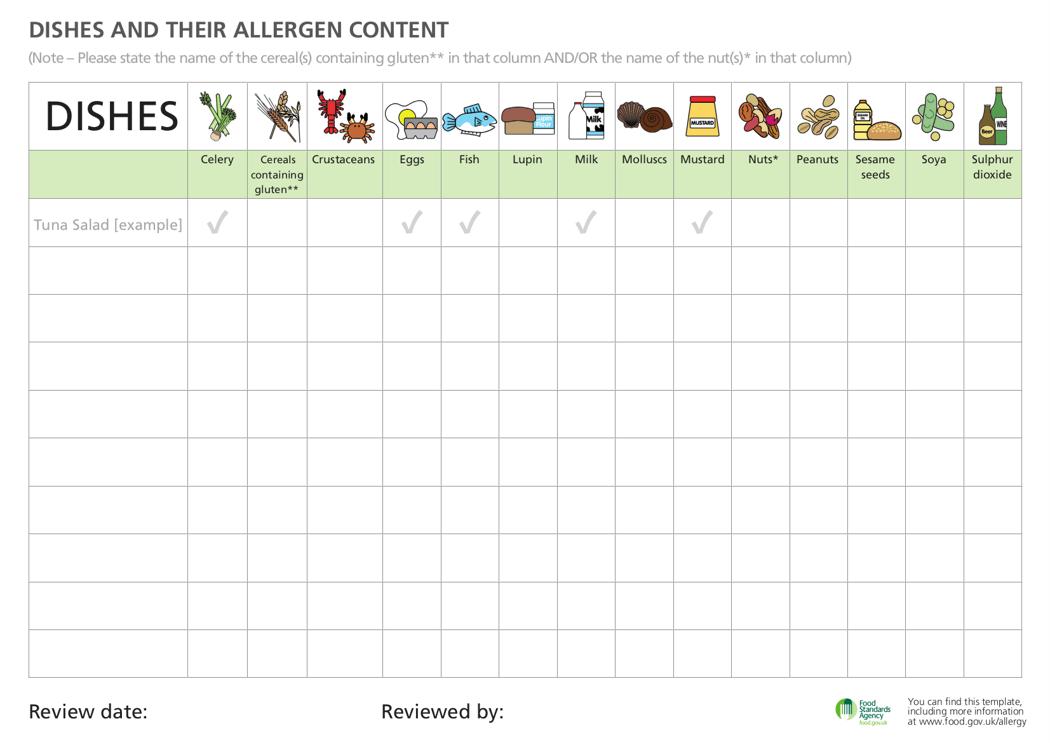

Step One: List all your dishes on the left-hand side.

Step two: Work through all your dishes and tick the relevant allergens. Remember to check all your ingredients and don’t forget ‘hidden’ allergens. For example, curry paste will often contain mustard.

Step three: Keep a copy of your matrix available for customers and a copy in your kitchen.

If you have a website, consider placing the allergen information online. This will present a professional image to customers.

You could also add a QR code for your website information to your allergy sign.

There are various electronic tools and systems available to purchase.

For most small business, the FSA allergen matrix is the most viable option.

Training records

Legally, everyone must be trained to the correct level. (In technical language, this is, “trained to a level commensurate with their workplace activities”).

At Hygienie, we offer a variety of training solutions including competitively priced e-learning.

We can help ensure you're training is legally compliant.

EHO INSPECTION

The duty manager has introduced themselves to EHO, and if you’re not on duty, they’ve called to inform you of the visit. If possible, try and attend the visit yourself.

EHO may examine the paperwork first, or more likely, they’ll head straight into the kitchen.

Ask if you can accompany the EHO. Be courteous and professional.

If possible, always accompany EHO on their visit; take notes, show interest, make a good impression. However, if EHO would rather be left alone, leave them to it!

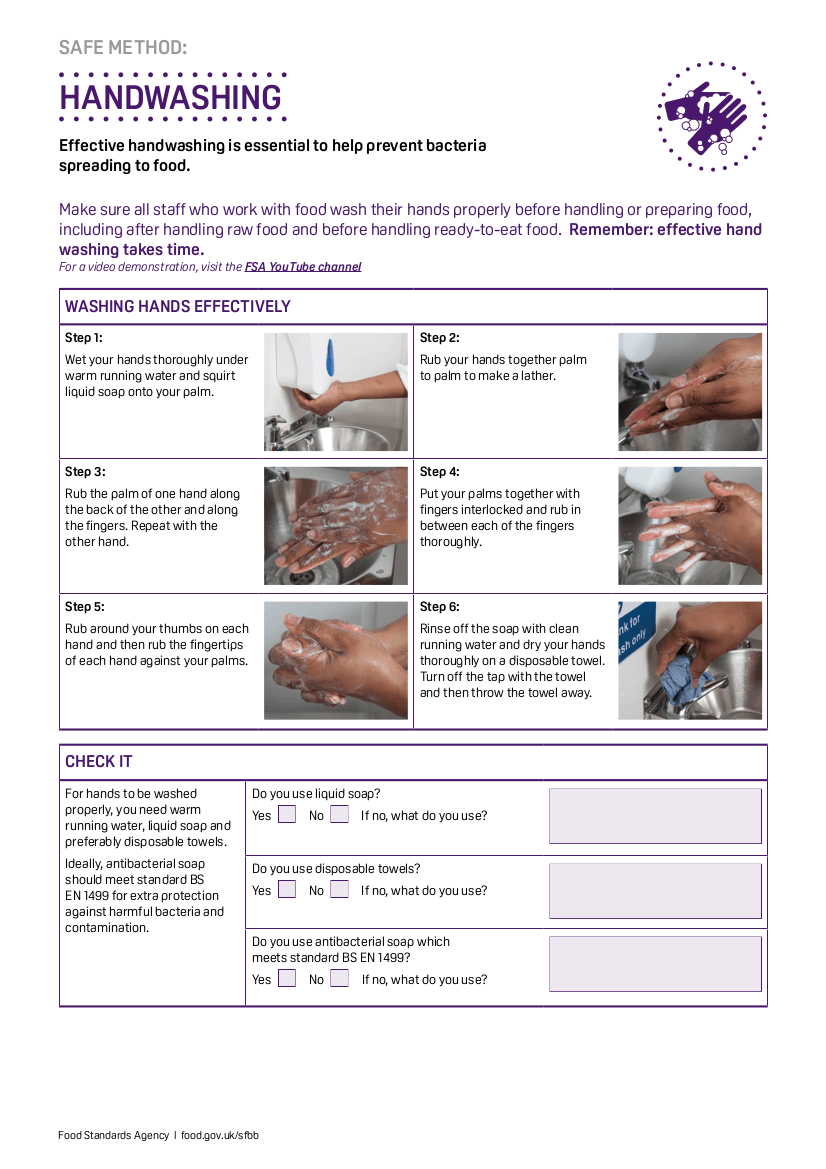

BASIC CHECKS

Temperature probe.

It's not a legal requirement to use a probe, but it's usually the best way to check cooking temperatures.

If you're using one, ensure the following:

- It's working

- It's clean and in good condition

- You have suitable probe wipes available (EHO heavily penalised sites for using baby wipes and surface cleaners).

A QUESTION FROM OUR LEVEL TWO FOOD SAFETY COURSE:

You can find suitable probes, and probe wipes, at reasonable prices, on Amazon or local catering suppliers.

Ensure probe wipes are clean and moist (some sites keep them in the fridge in a lidded container as this helps to prevent drying out).

If you don't have probe wipes, instruct staff to use paper towels and your disinfectant/ sanitiser. Probe wipes are preferred.

Some EHO also expect you to calibrate your probe on a regular basis (eg weekly).

Place in iced water (ideally in a metal container with plenty of ice). The probe should be zero degrees C. A tolerance of one degree either side is usually permitted (ie -1 to +1).

Place in a pan of water on a boiling water. The probe should be 100 degrees C.

Again, a tolerance of one degree either way is allowed.

You can add probe calibration procedures to your laminated guide.

1. FOOD PRODUCTION

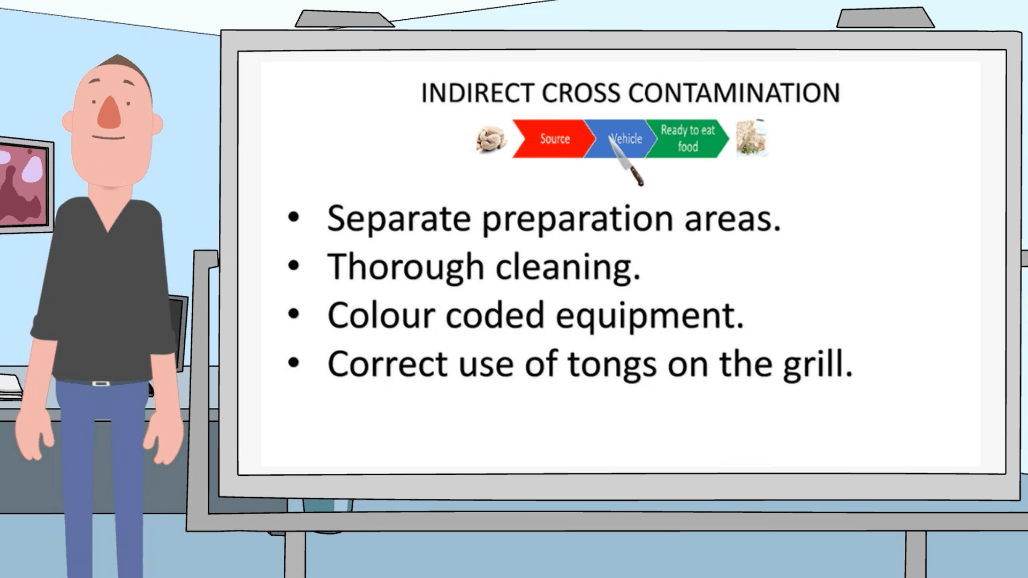

EHO will examine practices. Problems frequently raised include:

- Temperature control. Some food must be below 8C. Do not leave out at ambient temperature for too long. The maximum time this food can be held at ambient temperature is four hours. Therefore, small amounts, during busy periods should not be a problem.

- Cross contamination. Use the correct chopping boards and prepare raw food away from ready to eat food.

4. STRUCTURE, CLEANING AND PESTS

All EHO will thoroughly check your premises, using a torch.

Ensure you do the same on your management checks. When you’re carrying out your own checks use a torch, and look at different angles (look under/look up).

Ideally, task other members of staff to check cleaning too; no-one will see everything.

All areas must be thoroughly clean.

Here are examples of detailed cleaning where EHO often find issues:

- Tin opener blade.

- Wall to floor junctions under and behind equipment.

- Shelving.

- The underside of the soap dispenser.

EHO will be especially concerned with dirty hand contact surfaces such as fridge handles.

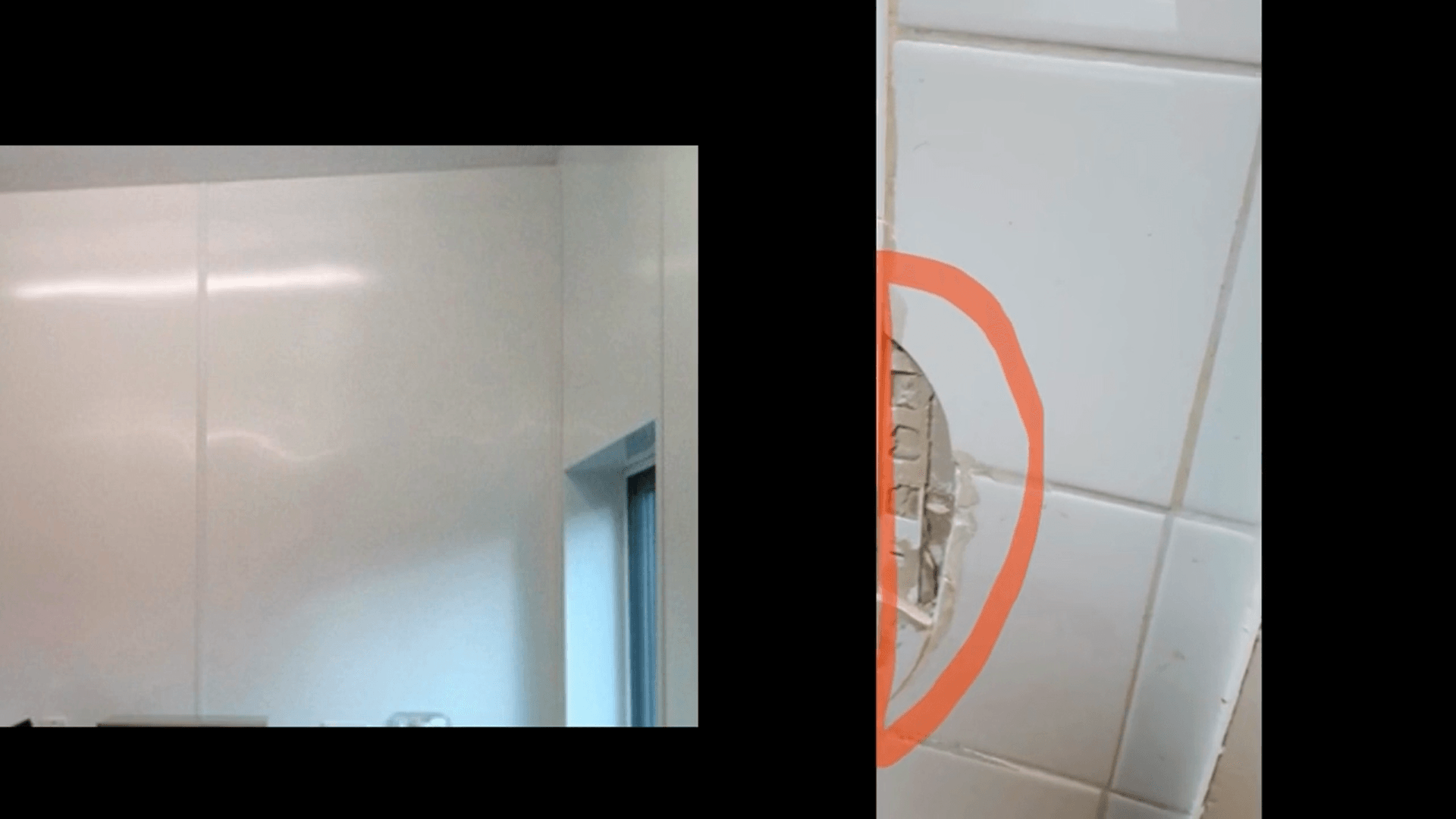

Structure:

All areas must be in good condition; smooth and cleanable.

Here is a list of areas where EHO often find issues:

- Damaged walls (e.g. cracks in tiles).

- Damaged floors.

- Damaged fridges such as seals.

- Heavily scored chopping boards.

Pests:

Ensure the site is pest free at all times.

It is not a legal requirement to employ a pest contractor. If you do employ a contractor, keep records in your ‘EHO box’.

If you don’t employ a contractor, carry out your own checks, record the findings and keep your own records.

EHO often score down because there are no fly screens on doors or windows, or because back doors are left open

Other areas:

Ensure bin areas and staff rooms/staff toilets are clean and tidy.

There should be two doors between a toilet and any food storage areas.

5. STORAGE

EHO will carefully examine fridges and other storage area's.

Ensure the following:

- All products stored at the correct temperature (legally chilled food below 8C).

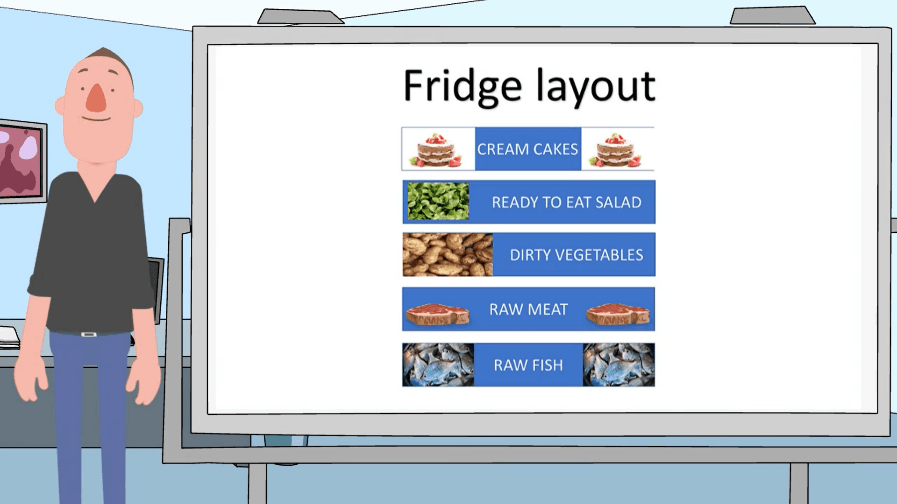

- Storage to prevent cross contamination (ideally raw food in a separate fridge. If not, at the bottom of the fridge). In general, the correct layout will be: raw food on the bottom, raw food which is ready to eat (e.g. carrots used in a salad) on the next shelf up, and all ready to eat foods on the top shelves.

- All food in date. Ideally, all food will be date labelled once opened (e.g. day of opening/preparation plus two days or follow manufacturers instructions). ALWAYS within manufacturers use by dates.

- No food on the floor. This is an issue frequently noted during inspections.

- All food in suitable containers, in good condition, and covered.

CLOSING MEETING

EHO have completed their visit.

Ask them to summarise their findings. Ask them what you need to focus on to improve.

Ask them if they'll give you the rating. Many won’t, but there’s no harm in asking!

Ensure you address any points raised as soon as possible (whilst EHO’s on site if you can).

YOUR RATING

We’ll discuss how your rating is calculated in a separate article. For now, be aware of this:

EHO’s findings are divided into three sections;

1. FOOD HYGIENE AND SAFETY

2. STRUCTURAL COMPLIANCE

3. CONFIDENCE IN MANAGEMENT

The most important thing to remember is that, if one of these sections receives a low rating; the overall score will be low.

Remember the food safety management system we spoke about in the beginning? If you don’t have one, the confidence in management section will have a low score, and therefore, so will your overall score.

THANKS

Thanks for reading this article, and good luck with your next inspection!